KINTA RUBBER WORKS SDN BHD

All Videos

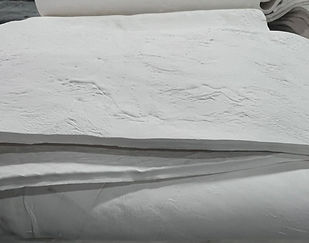

MASTERBATCH MIXING

)_.jpg)

Rubber masterbatch mixing incorporates a concentrated mixture of rubber and additives (such as carbon black, silica, curing agents, antioxidants, and plasticizers) into a raw rubber compound. This ensures uniform additive dispersion, improving the final rubber product's performance, processability, and consistency. Our expertise in custom rubber compounding allows us to create tailor-made rubber formulations to meet the unique needs of our clients. We work closely with businesses to develop customized rubber compounds that deliver exceptional performance.

Key Aspects of Rubber Masterbatch Mixing:

-

Masterbatch Composition – Typically includes rubber (like natural or synthetic rubber), fillers (e.g., carbon black), processing aids, and curing agents.

-

Rubber Compound Developer - Responsible for formulating and optimizing rubber compounds to meet specific performance, processing, and cost requirements.

-

Mixing Process – Done using internal mixers (Banbury mixer) or two-roll mills to blend the masterbatch into the raw rubber.

-

Advantages:

-

Ensures better dispersion of ingredients

-

Improves processability and uniformity

-

Reduces dust and handling issues compared to direct powder mixing

-

Enhances batch-to-batch consistency

-

Capacity - 200 L / 1 to 200kg

-

Types of Rubber Masterbatch Mixing:

-

Carbon Black Masterbatch – Improves reinforcement and wear resistance.

-

Color Masterbatch – Adds pigments for colored rubber products

-

Calendaring Compound –The calendaring compound is a specially formulated rubber mix designed to optimize the calendering process, ensuring smooth operation and high-quality output.

-

Base rubber (Natural Rubber, SBR, NBR, EPDM, etc.)

-

Fillers (Carbon Black, Silica)

-

Curing agents (Sulfur, Peroxides)

-

Application :

-

Conveyor Belts & Hoses (Durable rubber coatings)

-

Rubber Flooring & Sheets (Industrial and commercial use)

-

Tires & Inner Liners (Uniform rubber sheets for reinforcement)

-

Coated Fabrics & Insulation Sheets

-

-